Seal Coating

Seal Coating

Left untreated, asphalt pavement will deteriorate rapidly. The asphalt binder that holds the pavement together begins to oxidize and weather soon after installation. Moisture penetrates the asphalt, causing damage and deterioration to the pavement. Oil, gas, sunlight, and salt cause further damage to the pavement surface. All of this environmental distress is why asphalt goes from a newly laid fresh black appearance to a drab, aged, oxidized gray appearance.

Anderson Striping and Construction, Inc. utilizes high quality materials and cutting edge equipment with both spray and squeegee application options so that we can tailor our services to meet the specific needs of our customers asphalt while providing the best value possible.

Protects your asphalt investment by providing a protective layer that holds the pavement together and increases its lifespan.

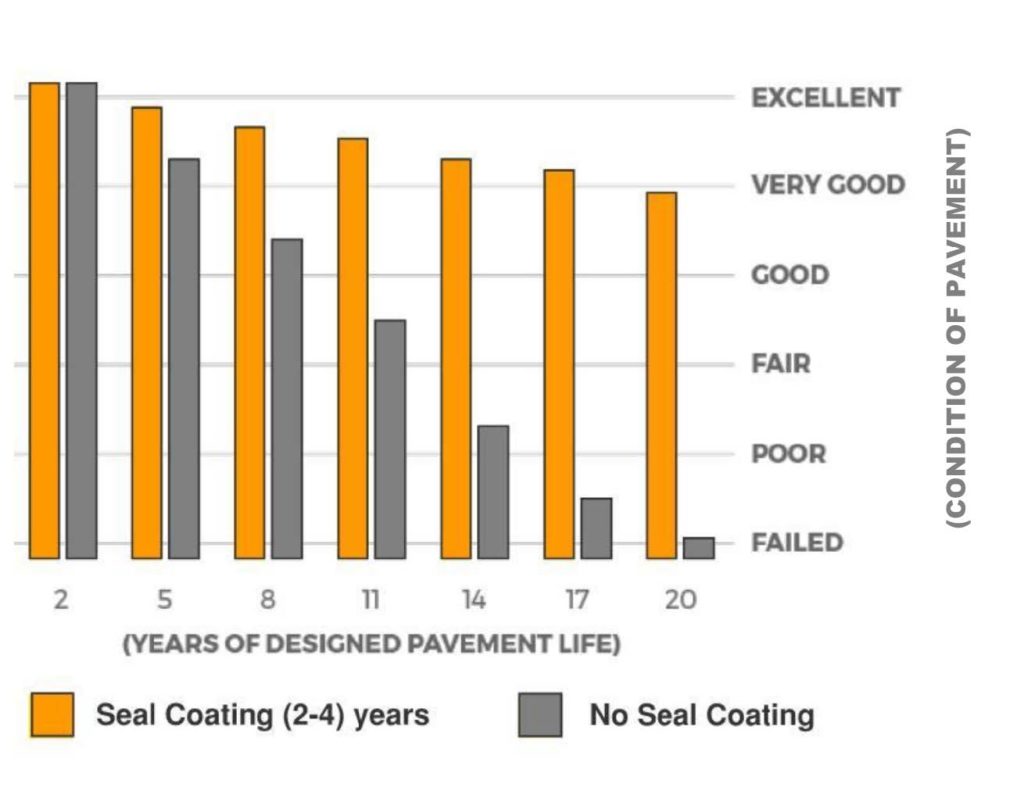

Seal coat can more than double the lifespan of your asphalt, saving you hundreds of thousands of dollars on asphalt repairs over time.

Seal coat applications are a fraction of the cost of asphalt paving and/or major asphalt repairs.

Its more cost effective to spend pennies per square foot maintaining your asphalt, then to let it degrade and have to spend many dollars per square foot replacing it.

FRequently Asked Questions

What is seal coating?

Seal coating is a preventive maintenance procedure that protects an asphalt surface by sealing the asphalt against the harmful effects of erosion, such as sun, water and frost. Seal coat slows oxidation of the asphaltic binder and reduces the loss of aggregates from the surface of the asphalt and, therefore, reduces maintenance costs and adds years of life to pavement. Seal coating is very inexpensive compared to new asphalt paving or asphalt repairs, and a regular seal coating regimen (every 2-4 years) can more than double the lifespan of your asphalt and save you hundreds of thousands of dollars over time.

Does seal coating fill cracks?

Seal coat itself only fills micro cracks in the surface, however part of the seal coat preparation process generally involves cleaning out cracks in the parking lots and filling them with a commercial grade bituminous crack fill that seals the cracks while still allowing them to flex due to the constant expansion and contraction that the asphalt is subject too. Large cracks in the asphalt surface (1″ or wider) do not benefit from the bituminous crack fill and should be repaired before seal coat is applied.

What are the weather requirements for applying seal coat?

Ambient temperatures should be at least 60 degrees and rising and below 110 degrees for seal coat application. Seal coat should not be applied in temperatures below 60 degrees, or when ambient temperatures are forecast to be 40 degrees or below during the next 48 hours. Seal coat should not be applied when rain is imminent or forecast within the next 48 hours. Seal coat that is applied in temperatures below 70 degrees will take longer to cure and will be more sensitive to water until cured.

When should seal coat be applied?

Seal coat should be applied every 2-4 years, depending on traffic and weather conditions. Seal coat should not.

Does seal coat repair damaged asphalt?

Seal coat is a preventative maintenance procedure that protects your asphalt and extends its lifespan. However, seal coat does not however repair asphalt that has already lost its structural integrity. Areas of failed asphalt like potholes, depressions, or alligatoring generally require removal and replacement of the asphalt itself as well as compaction of the base section and/or sub grade underneath.

Typically, if 30% or more of the total asphalt surface requires substantial removal, its more cost effective to defer the seal coating and spend your budget on

Does the asphalt need prep work prior to seal coating?

Yes, in order for seal coat to adhere properly, the surface of the asphalt must be cleaned thoroughly. All dirt and material must be removed, and any oil or grease spots should be treated with a primer before the seal coat is applied. Any areas of failed asphalt like potholes should be repaired before seal coating. Most asphalt surfaces also have cracks that should be filled before the seal coat is applied.

How long does it take to seal coat a parking lot?

Seal coat cure times vary based on temperature and sun exposure, however, we generally recommend keeping traffic off of a seal coated surface for 24 hours.

We have the capability to seal coat huge areas in a single day, so the total duration and phases are usually determined by how much area our customer can give us at a time.

Are there any beneficial additives for seal coat?

There are fast dry additives that can be combined with the seal coat to speed up the cure time.

There are also pre-mixed seal coat variants offered by the manufacturers that are polymer modified, which can result in enhanced wear characteristics.